Baker's dozen

Posted: Fri Dec 04, 2020 3:07 pm

Here for your viewing enjoyment is a "baker's dozen" of tips-by-pix.

First, I imagine many do not know that the float pivot pin in a GL1000 is directional? Yup. It is. It does not go in this way.

But it does go in this way. On all four carbs. The reason is the two holes are not the same size. Unusual for Keihin carbs and the GL1000 is the only Keihin I know of like this. Common on Mikunis however.

I expect it is not universally understood that the pivot pin has a taper on one end either. But it does. Nasty-looking pin, eh? More on this later.

Another gotcha here, the primary and secondary main jet o-rings. The correct ones come from only one source, as I have pointed out twice before. And it's not Honda and it is not in any kit (except, at one time at least, the Randakk kit). Using the wrong o-ring here results in the problem shown in the picture.

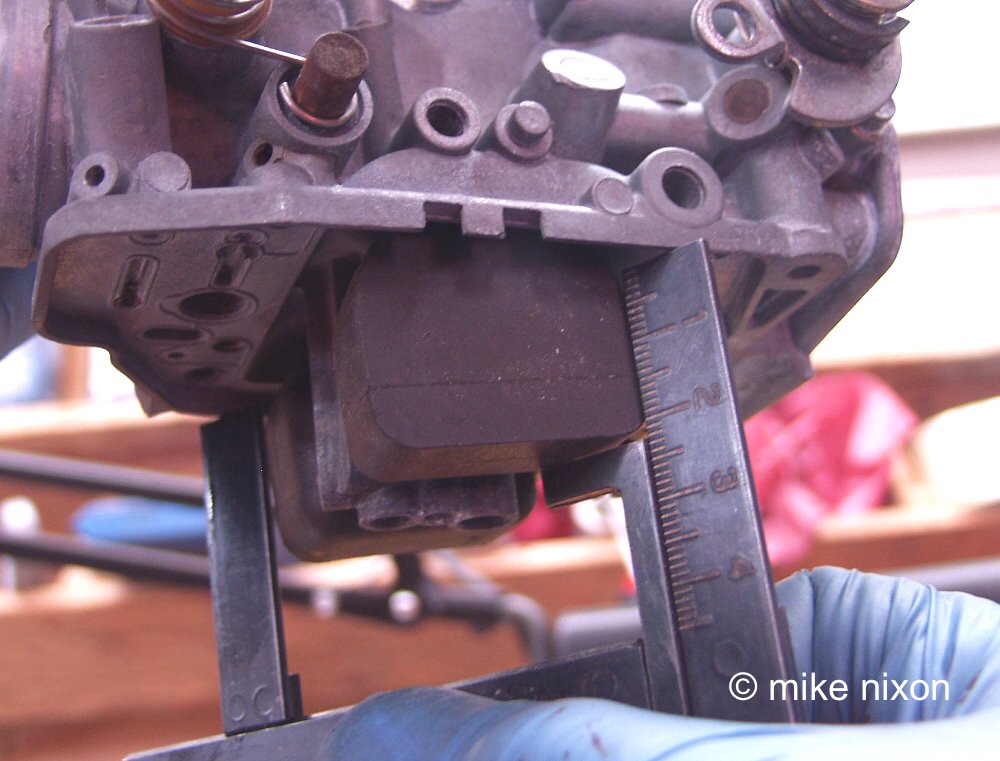

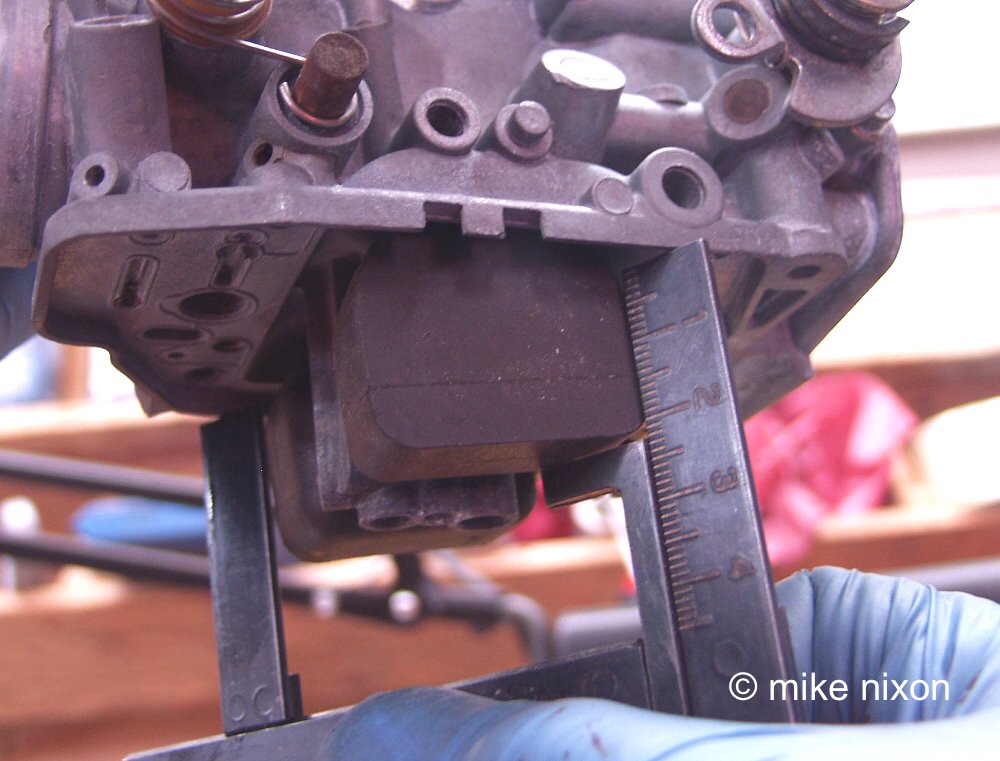

The correct way to check float level on the GL1000. You have to avoid the notches and the only way to do that is to angle the tool. The exact placement of the tool could be a little better in this pix, but you get the idea.

Another one. The dark junk on the slide is from the crankcase recirculation system. Or, Marvel Mystery Oil in the fuel. Either is a bad thing.

Here we have the aircut valve and its lower two o-rings. I always lightly glue them in place because putting the carbs on and taking them off usually involves temporarily removing this valve. Don't want to lose those babies.

This is the float pivot pin again, but now look at all the scaring on it. This comes from using pliers to remove the pin. Don't do that.

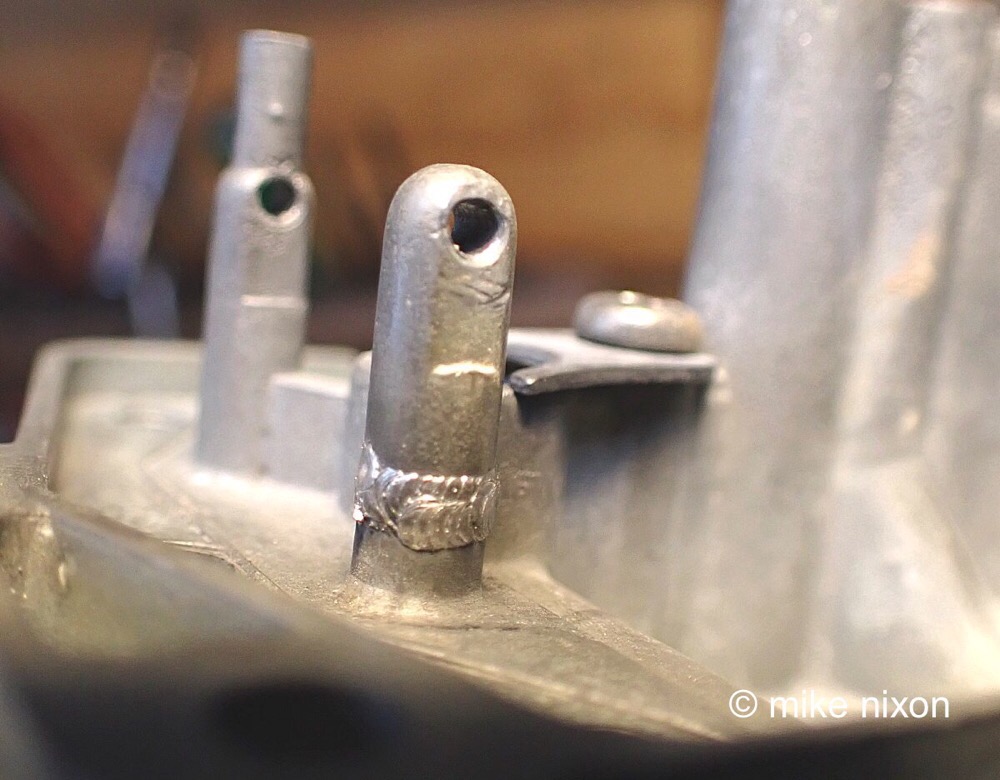

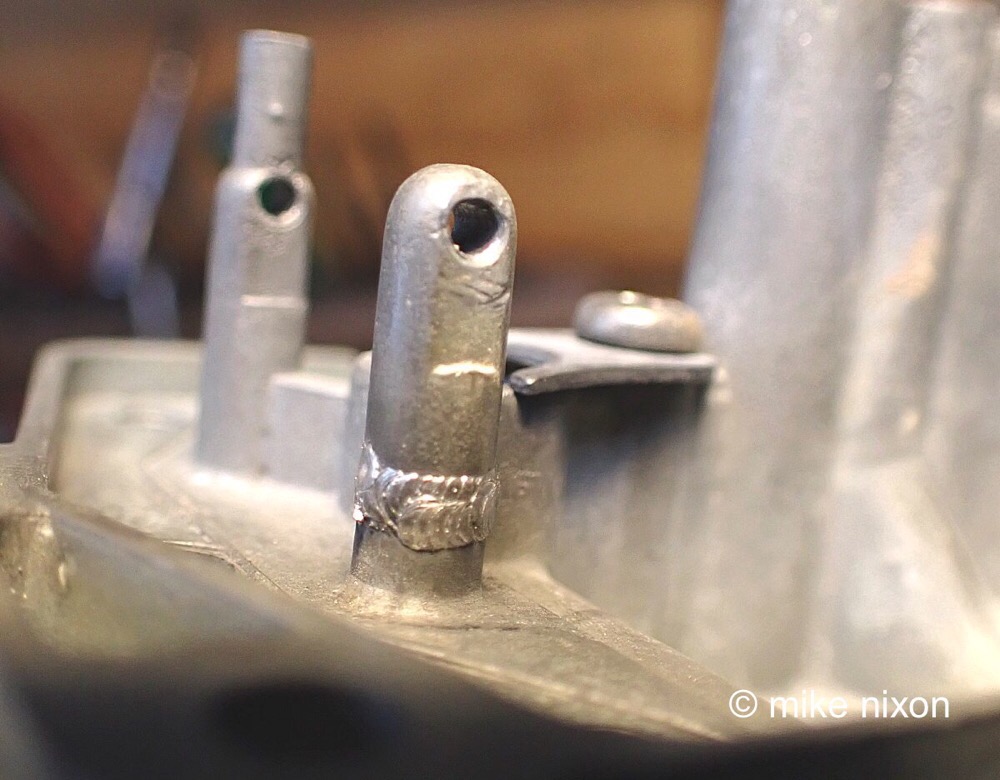

Here is just one reason why tearing up the pin is bad news. It is one of the reasons float pivot posts snap.

Here is how I repair this, by welding. The best of the handful of options to my way of thinking. Permanent.

This massive corrosion is not unusual on the GL1000. The zinc construction makes these carbs very corrosion-prone. This particular example is not salvagable.

However, if the corrosion is not too bad, the jet towers can be machined down to give the main jets new purchase. But only a little. The depth of the cross-drilled hole for the idle jet determines this.

First, I imagine many do not know that the float pivot pin in a GL1000 is directional? Yup. It is. It does not go in this way.

But it does go in this way. On all four carbs. The reason is the two holes are not the same size. Unusual for Keihin carbs and the GL1000 is the only Keihin I know of like this. Common on Mikunis however.

I expect it is not universally understood that the pivot pin has a taper on one end either. But it does. Nasty-looking pin, eh? More on this later.

Another gotcha here, the primary and secondary main jet o-rings. The correct ones come from only one source, as I have pointed out twice before. And it's not Honda and it is not in any kit (except, at one time at least, the Randakk kit). Using the wrong o-ring here results in the problem shown in the picture.

The correct way to check float level on the GL1000. You have to avoid the notches and the only way to do that is to angle the tool. The exact placement of the tool could be a little better in this pix, but you get the idea.

Another one. The dark junk on the slide is from the crankcase recirculation system. Or, Marvel Mystery Oil in the fuel. Either is a bad thing.

Here we have the aircut valve and its lower two o-rings. I always lightly glue them in place because putting the carbs on and taking them off usually involves temporarily removing this valve. Don't want to lose those babies.

This is the float pivot pin again, but now look at all the scaring on it. This comes from using pliers to remove the pin. Don't do that.

Here is just one reason why tearing up the pin is bad news. It is one of the reasons float pivot posts snap.

Here is how I repair this, by welding. The best of the handful of options to my way of thinking. Permanent.

This massive corrosion is not unusual on the GL1000. The zinc construction makes these carbs very corrosion-prone. This particular example is not salvagable.

However, if the corrosion is not too bad, the jet towers can be machined down to give the main jets new purchase. But only a little. The depth of the cross-drilled hole for the idle jet determines this.