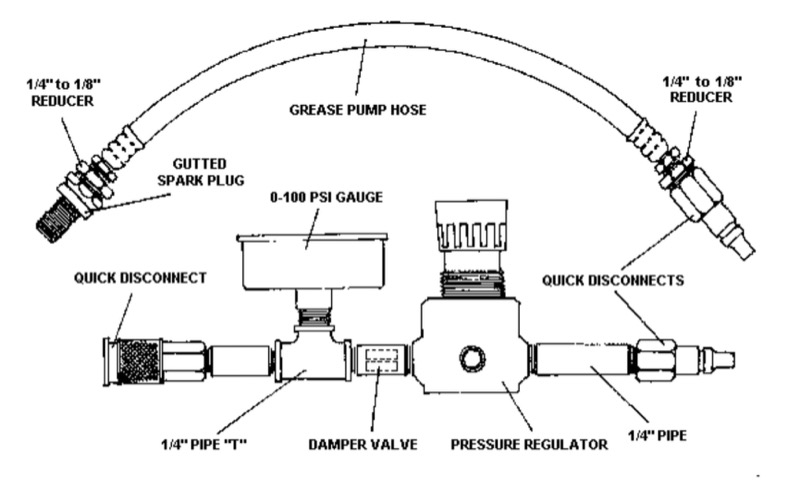

You can also make your own. Here's the rundown:

Pressure regulator . This is an automotive paint spray gun part. Grainger's is probably the cheapest, followed by Sears and Ace Hardware. EBay too. The 0~160 gauge that often comes with these regulators is, unfortunately, the wrong kind for our purposes. So we'll need to replace it with a 0~100. See below. Also, make sure your regulator comes with the block-off plugs for the two passages that you won't be using.

Pressure gauge. Get a quality, back-mount, 0-100 psi gauge. For the professional touch, carefully pry off the bezel and cover the faceplate with a new label. If you don't feel like re-labeling the gauge, no big deal. But you'll then have to read the gauge backwards; i.e. "10" would mean 90% leakdown. Not an intuitive way to use the tool. Better to relabel.

Spark plug adapter. Start by by clamping an old NGK spark plug in a vise (protected with wood or aluminum stock) and whacking off the porcelain with a well-aimed lateral hammer blow. Then grind or machine off the rolled-over seal above the hex, grind off the ground electrode, put the plug back in the vise and drive out the remaining porcelain with a drift. Tap the hex end with a 1/4" pipe tap. Screw the bugger onto a 1/4" to 1/8" pipe reducer, and that onto a 12" grease gun hose. Use pipe-sealing tape on all threads. Make a separate complete hose assembly for each engine you're going to test that has a differently-sized spark plug hole.

Damper valve. This essential part damps the gauge's needle movement. It's merely a restriction between the regulator and the gauge. The easiest way to make it is to fill the middle pipe with epoxy and afterward drill through it a 0.040" (#60 or 1mm drillbit) hole. You could also machine a tight-fitting plug and drill it.

Parts List

Miniature air pressure regulator

0-100 psi gauge, back-mount, metal case, removable bezel

12" grease gun hose

1/4" NPT quick disconnect fittings

1/4" plumbing pipe and "T" joint

1/4" to 1/8" NPT reducers (2)

Old spark plug

Teflon plumber's tape