find any so I made it myself.

What you see here is sectioned pieces of 1 3/4"od pipe bent to 70deg. Mitered to fit with 4 inserts. Stock runners are screwed into plywood to assure spacing and hold work.

the inserts are made by stretching a piece of 1 1/2"od to 1 11/16"od . This will give a snug factory type fit in the rubber boots.

Here is the cross-tube. Using the 1 3/4"od. Measure long and miter to fit. This one was about 6 1/2" long

A small piece of 1 3/4"od for the plenum riser. photo is 1st generation Ol' Sparky manifold. I now weld the riser to the mounting plate BEFORE welding to crossover tube.

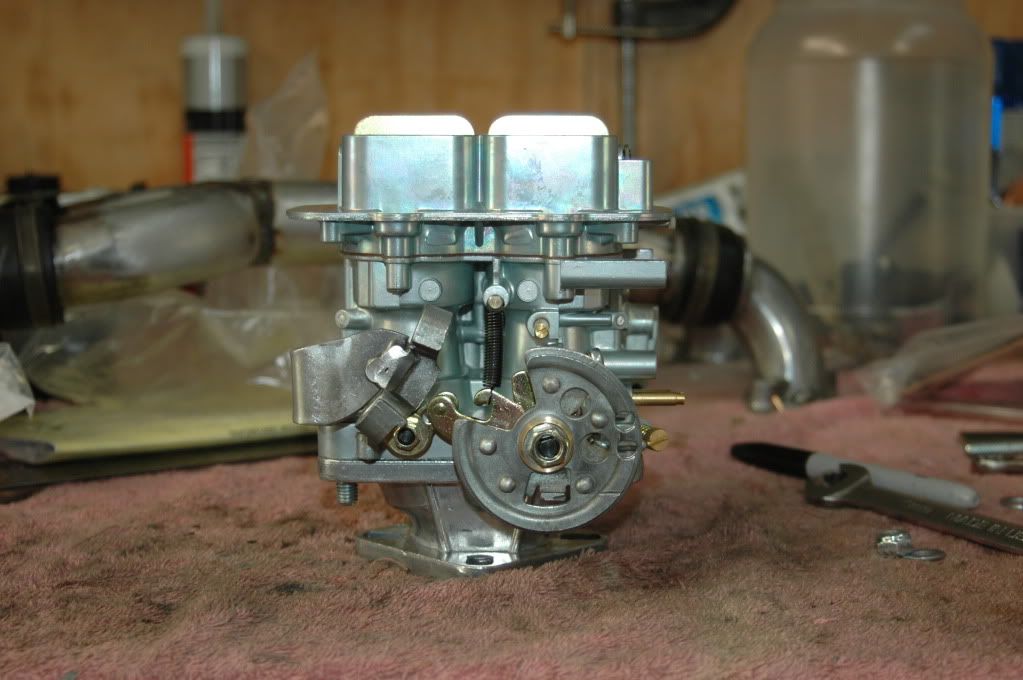

The adapter plate is a 3"x3"x3/16". (I welded 2pcs. of 2" side by side)

I used the adapter kit gasket as a template for the bore and mounting screws.

TIP; tack two bolts on the L & R sides of the plate from the underside. This makes install & removal of the carb much easier.

photo; tapping the carb hold down bolts.

photo; using hole saw to cut welds and pass thru.

photo; manifold ready for Holley or Weber, 1 or 2bbl carb (32/36 Weber shown)

More to come; Carb kits, adapters, throttle set-up, and... to choke or not to choke?