http://www.babcox.com/editorial/ar/eb70536.htm

I think the link above died try this one.

http://www.enginebuildermag.com/Article ... t_use.aspx

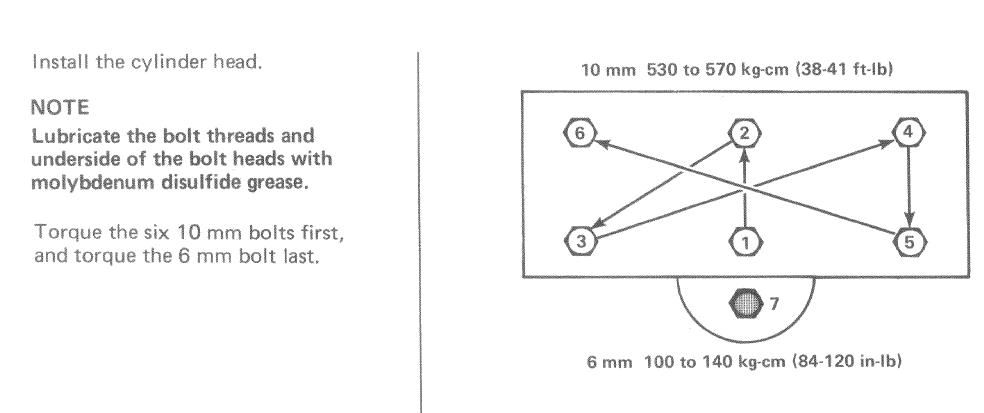

I bring this up due to the recent rash of head gasket failures that we have seen discussed here. The note (Below) from the Manual is there for a reason. This step is critical to achieving proper head clamping pressure. According to the article (above) lubricated bolts can achieve 20-25% more clamping pressure than non lubricated bolts. Any decent Moly Grease will suffice but make sure the threads of the head bolts are cleaned then lightly lubed along with the undersides of the bolt heads before torquing them.

So basically not lubing the bolts is ensuring that your head is not properly torqued and is a sure fire way to have a head gasket failure before it's time.

Also make sure to observe the new torque values (42-45 foot lbs) per the service bulletin http://www.ngwclub.com/File%20Share/100 ... 0%2314.pdf